At the centre of Bridge is an iconic, yet intriguing, bridge structure.

International designer Dan Potra worked alongside structural engineer Neal Fletcher, circus specialist Tarn Aitken and a skilled team of theatrical technicians and fabricators to create a workable design for the bridge.

It needed to be visually powerful, structurally secure and yet transportable.

James Dyer at Bay Productions explains how the design then became reality:

“Normally we would expect a bridge to behave in a particular way, but this bridge is structurally different to the norm.

The designer and engineers gave us a cantilevered design, which meant we had to ensure the bridge was strong enough for circus artists to perform from safely. The design also showed that some areas of the bridge should look like narrow stonework – our challenge was to find the materials that could perform for both the structural and aesthetic needs."

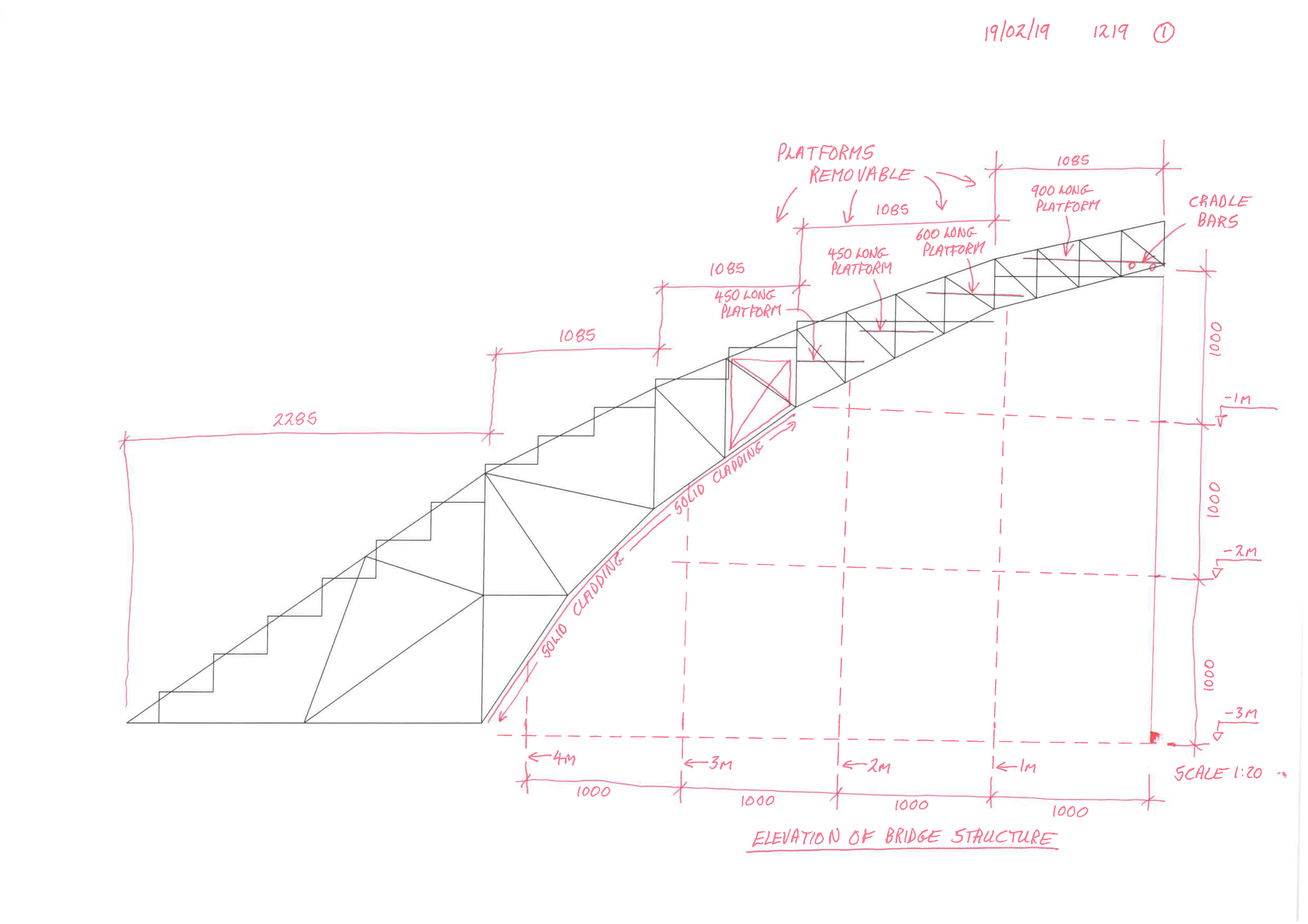

One of many working drawings of the bridge

3D Modelling

"We use 3D modelling to help us work out the best materials to use.

The basic structure is made of steel, which we then clad in a waterproof and durable twin wall made of polycarbonate.

The outside cladding of the wall is only 16mm thick, which allows for light to be projected effectively through its surface."

Fabricating the bridge at Bay Productions

Construction

"The steel frame started life as long tubes, which we transform in a process known as ‘rolling’.

We make 1-to-1 scale templates onto large sheets of paper, and then ‘roll’ the steel through a machine to create a curved tubular finish that fits the template.

It’s a very hands-on process. The tubes were then fixed onto extremely heavy-duty steel beams to provide ballast.

The Bridge was then clad with sheets of Twin Wall and Foamex, which were precision cut on a CNC machine, before being finished with Idenden, a textured co-polymer substance that looks like render but does not flake or crack. The idea was to make the Bridge appear to be made of solid blocks of stone or concrete.

The final step was to add the technical supports for the performing artists, such as the socket positions for wires and ropes."

The bridge underwent many weeks of testing

Read On: Building Bridges